By Shane Loughlin

Like many other industries, farming and agriculture are changing. There are many drivers for these changes, but one that is largely regarded as positive is technology.

Farmers now commonly use drones to monitor livestock and locate escaped animals, for example, while communication technologies and cloud computing are streamlining business processes and making elements of farming more efficient.

Automation technologies are another key driver for change in the agricultural industry.

Today, most major tractor and agricultural machinery manufacturers have automated options in their product line-ups, i.e. where machines perform functions that are traditionally performed by the farmer.

These technologies, based on Industry 4.0 principles, allow the farmer to programme a specific operation in a field. The system then calculates the most efficient approach before using satellite navigation to autonomously steer and/or guide the machine. This is known as precision farming.

There are significant benefits to this technology including increased productivity. It’s not surprising, therefore, that the agricultural industry is showing enthusiasm and excitement.

The Downside

There are downsides to the above, however, largely because the automation and precision farming solutions currently available are large-scale. These problems are particularly acute when you look at them through the eyes of the small farmer.

The downsides fall into two major categories:

- Cost – the current costs of these systems are viable for large farms, but for small farms, the costs are prohibitive

- Application – the terrain on small farms is generally unsuitable for the large-scale automation solutions that are currently available from major manufacturers

To put this in perspective, 37 percent of Irish farms are regarded as small farms, with small farms accounting for 16% of Ireland’s farmland. These figures are from Teagasc National Farm Survey. Other important findings from that survey include:

- There are big differences in the regions of Ireland. In the BMW region (Border, Midland, and West), 44 percent of farms are small farms. In the rest of the country, the figure is 30 percent.

- Compared to the early 1990s, more small farmers are now over 65, fewer small farms can employ a full-time worker, and there are fewer farmers who say farming is their only occupation.

- Around 50 percent of small farms nationally are regarded as economically vulnerable

Therefore, while farming automation and precision farming technologies are pushing the agricultural industry forward, a significant percentage of farmers are being left behind.

Changing the Context

This problem, however, does not rest with the technology. Instead, it rests with the way these technologies are being applied.

In other words, the focus of tractor and machinery manufacturers to date has been on large farm businesses. From a profit-making perspective, this is understandable. However, the large size of these solutions mean they can only be used in favourable weather conditions.

Introducing Feirm CHLISTE

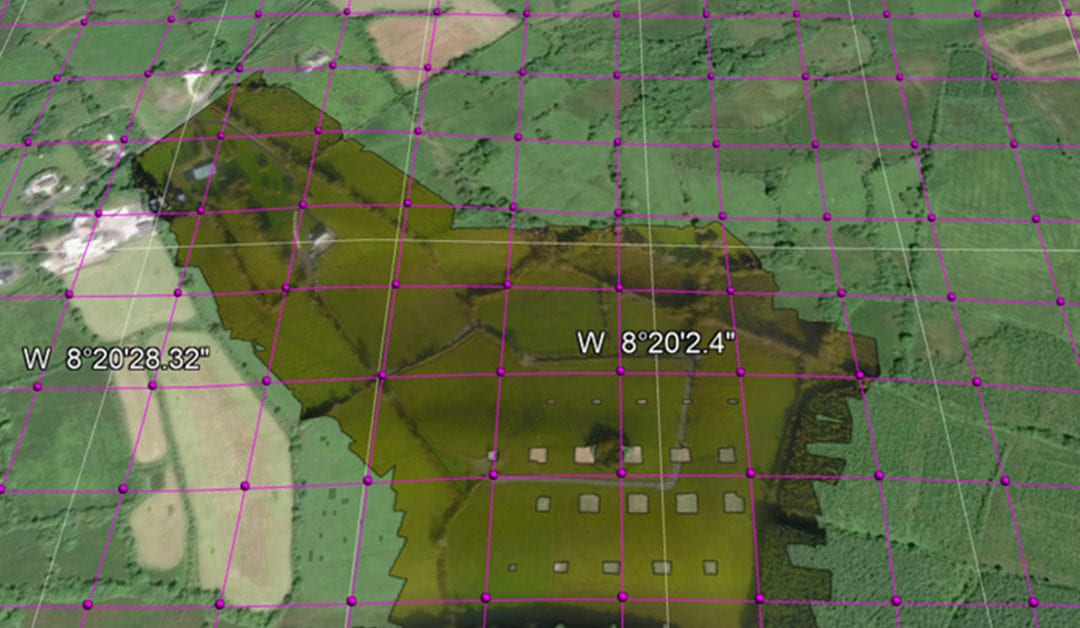

Feirm CHLISTE is Irish for Smart Farm. It is a 10-year research project using a real farm on the Sligo-Leitrim border, in the heart of the BMW region. The project involves:

- Adapting the farm for the implementation of automation technologies

- Modifying tractors and ATVs to operate autonomously. Safety regulations mean these vehicles must be small, but they will be able to operate 24/7 without a driver. They will also be light and manoeuvrable, making it possible for them to operate in poor weather conditions.

- Developing software solutions that will make the Smart Farm a reality

- Implementing these technologies in a real farming situation and all that entails – changing weather conditions, machine breakdowns, connectivity issues, and more

In recent times, the farm being used in the project was farmed using low intensity and non-interventionist methods.

The objective of Feirm CHLISTE is to use automation and precision farming technologies to modify the use of the land, changing it from random grass and weed growth to highly data-centric grass production.

Who Is Involved in the Project?

The lead facilitator of Feirm CHLISTE is me, Shane Loughlin, co-founder and CTO of SL Controls. The programme is part of E-Cubers, an initiative I also launched.

E-Cubers focuses on Equipment Engineering Excellence and promotes the career of Equipment Systems Engineering. It is Equipment Systems Engineers who will develop future solutions for a wide range of industries that will be similar to those that are the subject of the Feirm CHLISTE project.

Others involved in the project include IT Sligo, TY students from Coola Post Primary School in Sligo, and master’s students at the University of Limerick. The project is supported through E-Cubers by LEO Sligo.

What’s Next?

While Feirm CHLISTE has been in the incubation stage for some time now, we are still in the early days of the project. The official timescale runs from this year, 2019, to 2029, although there will be multiple milestones along the way.

The biggest one coming up this year is a presentation at the National Ploughing Championships in Fenagh, County Carlow in September. At that event, we’ll be demonstrating some of the equipment and technologies we have developed.

To stay up-to-date with Feirm CHLISTE, sign up to the E-Cubers newsletter and follow us on social media.