Industry 4.0 is a term used to describe a revolution that is happening in industry, the wider business community, the country’s economy, and society more generally. It is something that everyone entering the jobs’ market in the future, as well as those already in the jobs’ market, should be excited about as it presents fantastic opportunities.

To start this explanation of Industry 4.0, however, let’s go back to the beginning. You see, Industry 4.0 is the fourth industrial revolution. To properly understand it, you need to get an overview of the three that went before.

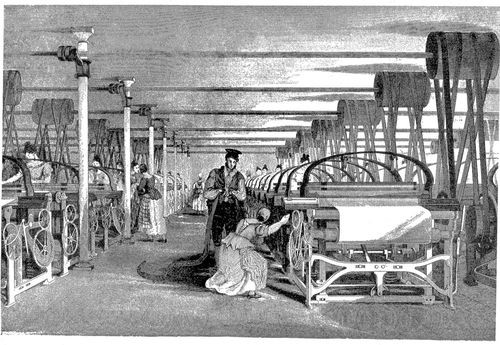

First Industrial Revolution

When – 1760s to the 1840s

What – saw the introduction of steam and water powered machines that enabled mechanical production. Relatively unskilled labour operated these machines, replacing the skilled craftsmen that came before them. This changed the economic structure in many societies, with industry replacing agriculture as the foundation of the economy.

Second Industrial Revolution

When – 1870s to the start of World War I in 1914

What – new sources of energy were the driving force behind the Second Industrial Revolution, with electricity, gas, and oil being used to power larger and more efficient machines. The steel industry grew, and new communication technologies were developed, particularly the telegraph and telephone. Transportation changed significantly too with the introduction of cars, lorries, and other new modes of transport. In addition, economic models became increasingly based on large factories.

Third Industrial Revolution

When – Sometime in the 1950s to the early 2000s

What – the Third Industrial Revolution is sometimes referred to as the digital revolution. It covers the period when industry and other sectors moved forward from mechanical and analogue electric technologies. The replacement was technology based on digital electronics. The technologies that were the main drivers for this revolution were the transistor, microprocessor, and computer. Advances in telecommunication technologies were also critical. In factories, PLCs (Programmable Logic Controllers) and robotic technologies transformed manufacturing.

Fourth Industrial Revolution

When – Today

What – …

What is the Fourth Industrial Revolution?

The developments that took place between the first and third industrial revolutions paved the way for the opportunities that exist today within the Fourth Industrial Revolution, otherwise known as Industry 4.0.

So, what is Industry 4.0?

At the beginning of Industry 4.0, the internet already existed, machines had sensors, and it was possible to video call anyone in the world from a smartphone. In manufacturing environments, robots were commonplace, as were automated processes.

How much further could Industry 4.0 go?

The answer lies in the term digitalisation.

To understand this, it’s important to understand the difference between digitisation and digitALISAtion (or digitALIZAtion using the American spelling).

Digitisation is what happened in the Third Industrial Revolution. In simple terms, this meant taking analogue or manual processes and digitising them using computers, PLCs, robots, the internet, etc.

DigitALISAtion, on the other hand, is another way of describing a process known as digital transformation. This means transforming a business – any business in any industry – into a digital business.

This occurs when all elements and units of the business are digitalised, connecting them like never before.

The Internet of Things Example

A good way of explaining this is by using an often-used reference to the Internet of Things, i.e. a smart fridge. A smart fridge of the future will be able to do a lot more things than a normal fridge today. This includes:

- Monitoring your supply of food

- Predicting when you are going to run out of a food item and re-ordering it, so you are never without

- Ensuring all the food in your fridge is fresh enough to eat and recommending when you should throw something out

- Assessing your diet and giving you recommendations on how to eat healthier or achieve your goals

Now take this concept into a manufacturing environment. Some of the functions in a manufacturing business include:

- The supply chain – the purchase of raw materials

- The production process, including quality control – the factory floor

- The distribution chain – getting the product into the hands of customers/end users

- Customer service – getting feedback from customers and managing customer complaints

So, where a smart fridge can monitor your food, re-ordering and making real-time recommendations, a smart factory will control the entire product lifecycle, interlinking all the above business elements across multiple factories in different geographical locations.

This will change the manufacturing industry in a variety of ways. Some examples include:

- Automated ordering of raw materials based not only on current demand levels, but predicted future demand

- Improved product quality by linking customer feedback and real-time usage data to the product development process

- Reducing factory downtime and product supply disruptions through predictive machine maintenance, where machine learning algorithms monitor machines to identify problems before a breakdown occurs and then plan maintenance at a time that will cause as little disruption to supply as possible

- Allowing support engineers to be in the same room as a technician in another factory in another country, helping them resolve an issue using virtual and augmented reality

- Production processes that don’t require a mass manufacturing approach to remain profitable but can, instead, run efficiently in small production runs – theoretically, down to production runs of one

What Does Industry 4.0 Mean for Your Career?

The work environment is changing and will continue to do so over the coming years and decades. The truth is, some of these changes will involve some jobs becoming obsolete.

This is only part of the story, however, as Industry 4.0 offers a fantastic opportunity. So, while some jobs will disappear, a whole raft of new jobs will be created – more than the number of jobs lost.

Many of the new jobs will be highly-skilled, with engineering being one of the most important.

Businesses will benefit from Industry 4.0 because they will become more profitable and competitive. Consumers will benefit too, as they will get newer and better-quality products in addition to higher standards of customer service.

Workers will also benefit, though, particularly those who train to become an Equipment Systems Engineer. Find out more today.